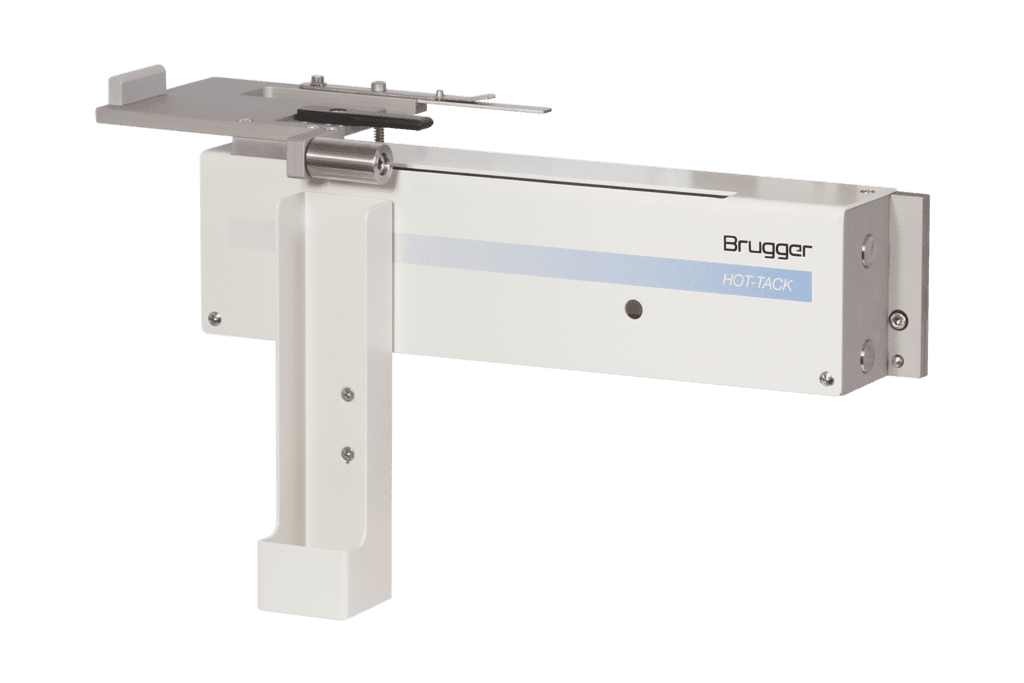

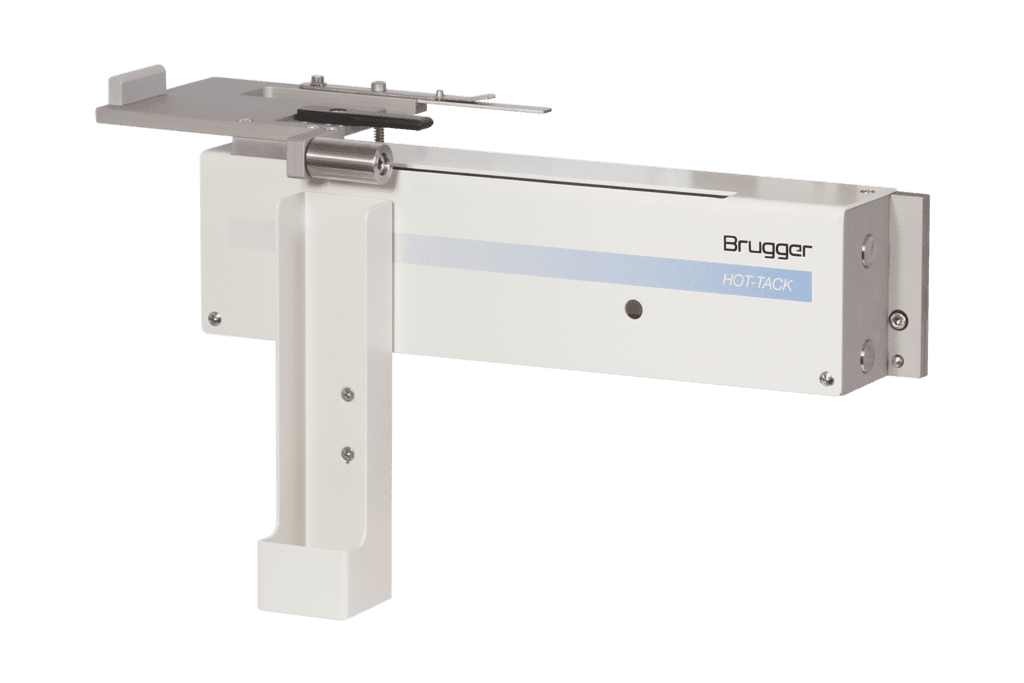

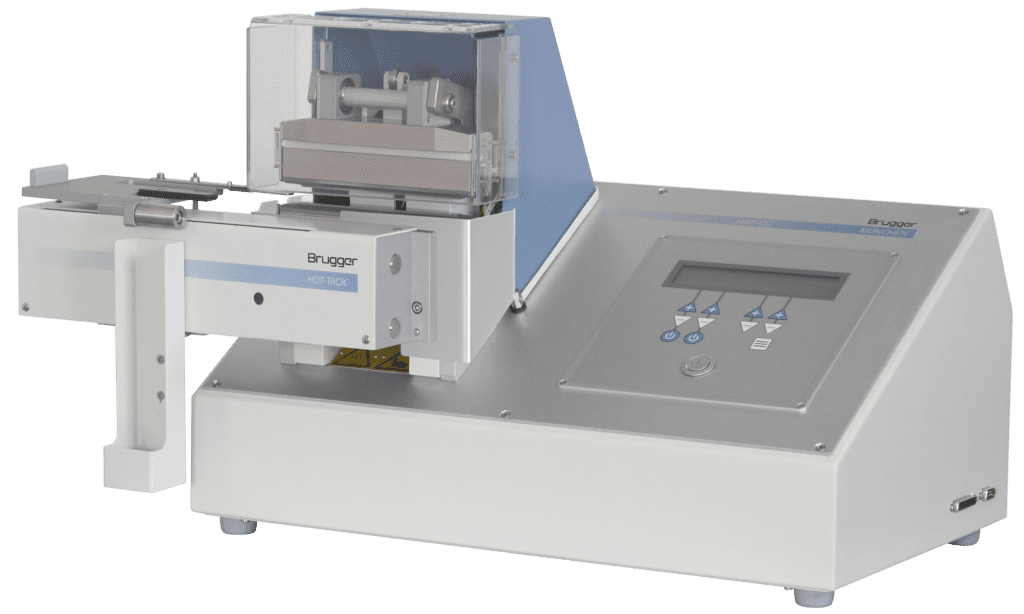

Hot Tack Attachment

… enables you to quickly determine the strength of sealing seams immediately after heat sealing and fits to all HSG models.

- Determination of the Hot Tack properties

- For all HSG / -C / -CC

- Hot-Tack according to DIN 55571-1

How it works

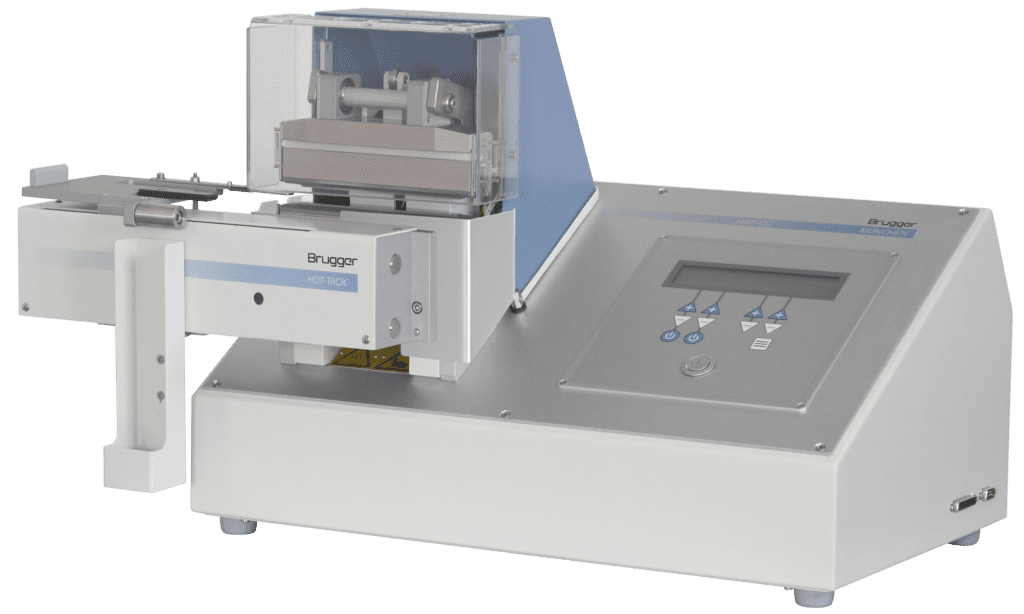

This HSG accessory enables you to quickly determine the strength of sealing seams immediately after heat sealing. This user-friendly accessory can be quickly attached together with special sealing jaws. To optimise the speed of the process, you may wish to produce exact samples with our Strip Cutter (STR).

Immediately after sealing the two sealed samples are dropped on a wedge by means of a floating weight (50 to 425 g) to split the hot seal seam. The length of the split seam depends on the Hot Tack properties of the material.

After completion of the Hot Tack test you simply need to measure the length of the remaining (non-split) sealing seam and document the result. An optional Microsoft® Access based Software enables you to document your test results with a click of the mouse. The whole procedure – from testing to documentation – is only a matter of a few minutes.

This test enables you to determine the exact Hot Tack properties of various materials with a minimum of effort. This accessory is indispensable for efficient QA procedures during production as well as for the determination of the appropriate sealing parameters during development.

Technical Details

| Test method | Qualtitative determination of the Hot Tack properties by dropping the freshly sealed seam on a split mandrel using a falling weight |

| Set of weights | 50 g up tp 425 g |

| Sealing Jaws | 40 mm x 20 mm, teflonised |

| Test strips | 15 mm width, length < 250 mm |

| Dimensions | 40 x 18 x 25 cm |

| Weight | 4,5 kg |

| Storage temperature | 0 °C – 50 °C |

| Working temperature | 15 °C – 35 °C |

| Relative humidity | max. 80 %, non-condensing |

| Hot Tack connection | via internal HSG treadle |

| Standard | DIN 55571-1, Hot-Tack – Part 1: Position measuring devices |

Optional accessories