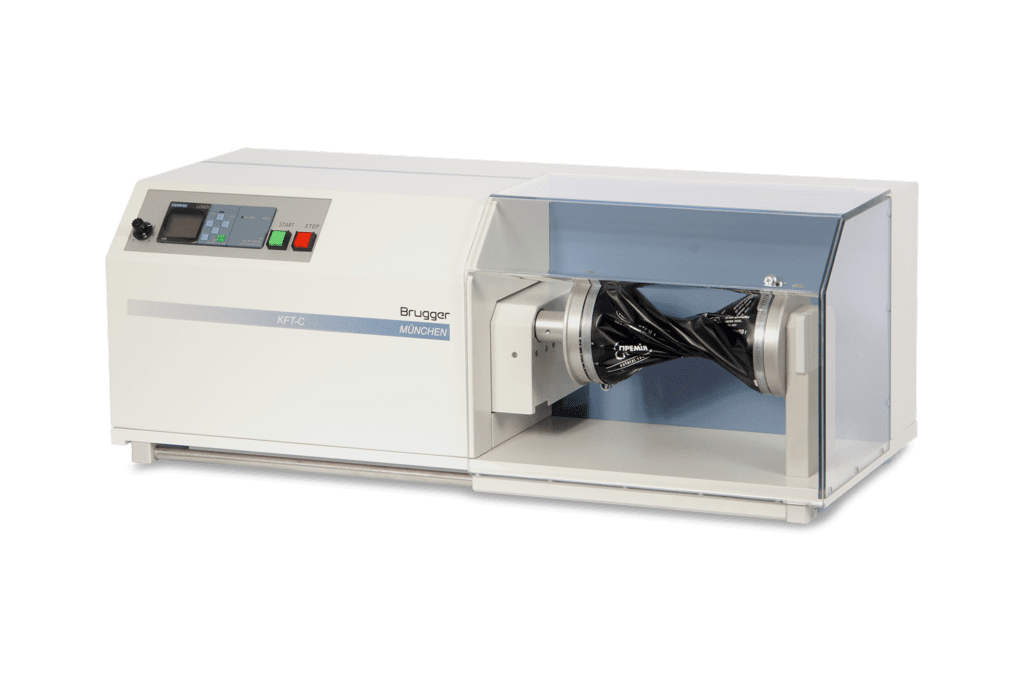

Flex Durability Tester KFT-C

… is used for simulating a creasing strain to films according to Gelbo Flex Testing (ASTM F-392) to determine the flex durability.

- Testing of flex durability

- ASTM F 392-93 standard

- Fixed cycles according to ASTM

- Or free adjustable number of cycles

How the Flex Durability Tester KFT-C works

The Flex Durability Tester simulates stress, which flexible packaging materials (such as coated or vapor-coated paper, plastic films and laminated material) may be subject during the automated packaging process. The KFT-C covers the determination of the flex resistance of flexible barrier materials with a high repeatability. After the test, any failure of the barrier can be determined by a gas permeability test (using our GDP-C tester) and/or by a water permeability test (using our WDDG tester). Physical holes through the material can be detected by the colored-turpentine-pinhole test.

The device uses a stationary and a movable mandrel of 90 mm diameter each. The specimen is affixed between the two mandrels in the shape of a cylinder. To do this, both ends of the specimen will be affixed with a locking onto each mandrel. In this initial position, the distance between the mandrels is approx. 180 mm (face to face). Two different motion cycles are described in the ASTM F 392-93 standard: One motion cycle uses a twisting angle of 400° and a horizontal move of 80 mm simultaneously (short stroke). The other motion cycle uses a twisting angle of 440° and a horizontal move of 90 mm simultaneously, followed by a single horizontal movement of 65 mm without twisting (long stroke). The frequency for both motion cycles is at a rate of approximately 45 cpm.

A logic module interprets the information from 7 different contactless switching sensors and controls the valves for both pneumatic linear actuators. Using the selector switch, the 5 different standard testing conditions can be set. Additionally the operator can choose any desired numbers of cycles for both different types of motion cycles. The actual testing condition is shown in the LCD-display on the logic module. During a running test the current number of cycles is also indicated in this LCD-display.

Technical Details

| Testing Standard | Reproducible simulation of mechanical stress to determine the flex durability on films in accordance to the ASTM F392-74 standard |

| Specimen dimension | DIN A4 / 210 mm x 295 mm |

| Compressive strain (long stroke) | 155 mm |

| Compressive strain (short stroke) | 80 mm |

| Angle of twist (long stroke) | 440° (the first 90 mm during the compressive strain) |

| Angle of twist (short stroke) | 400° (during the complete 80 mm compressive strain) |

| Testing conditions according the ASTM F392-74 standard | Condition A: long stroke / 2700 Cycles Condition B: long stroke / 900 Cycles Condition C: long stroke / 270 Cycles Condition D: long stroke / 20 Cycles Condition E: short stroke / 20 Cycles |

| Additional testing conditions | long stroke / 1 up to 999999 Cycles short stroke / 1 up to 999999 Cycles |

| Stroke frequency | approximately 45 per minute |

| Dimensions | 69 x 27 x 30 cm |

| Weight | 27.5 kg |

| Storage temperature | 10 °C – 40 °C |

| Operating temperature | 15 °C – 35 °C |

| Relative humidity | 80 % maximum, not condensing |

| Electrical connection | 100 – 240 V/50 – 60 Hz, Current maximum 1,5 A primary / 24 V DC, maximum 1,88 A secondary |

| Compressed air supply | 5 up to 10 bar |