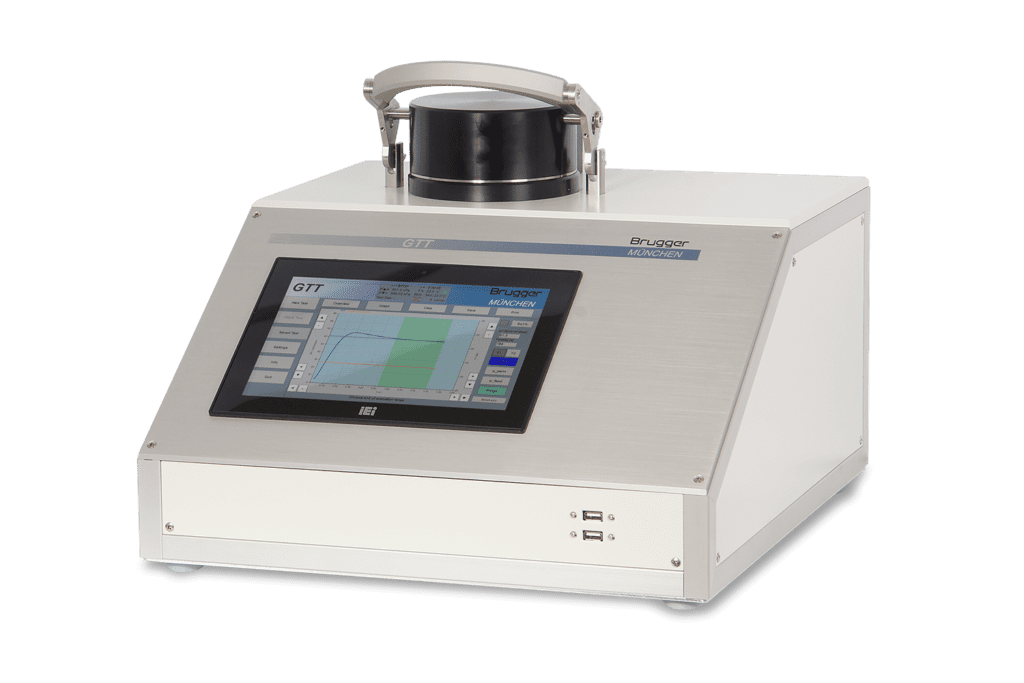

Gas-Transmission-Tester GTT

… is build for the determination of the gas permeability of films. It has an integrated touch panel for control and evaluation, as well as an intern temperature control.

- Different testing gases

- Integrated panel PC

- Internal temperature control

- Enhance evaluation

How it works

Our new GTT is a gas permeability tester that combines cutting-edge technology with the proven robust measuring principle of its predecessor, the GDP-C.

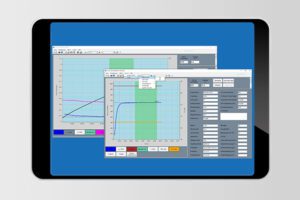

This makes the GTT an exceptionally compact device with a high-resolution touchscreen for inputting all the data needed for measurements and outputting analysis results.

A wireless keyboard (and wireless mouse) can also be used to enter data if required. Even more connectivity options are provided in the form of two readily available USB connections on the front of the device and a LAN port at the back. There is no need for an additional PC to control the GTT or evaluate its data.

This new model has replaced the extremely energy-hungry external water bath thermostat with an energy-efficient electrothermal temperature control device. This means that the GTT is easy to install without extra apparatus (except a vacuum pump) and is ready to use as soon as it has been set up.

The GTT also boasts the following features

- The device has been designed without any wear parts, making it exceptionally low-maintenance.

- It comes with a highly robust sensor (piezoresistive pressure sensor) and can withstand the sudden ingress of air during a measurement without being damaged in any way. It is also immune from the oversaturation that can affect electrochemical sensors.

- The combination of an extremely low measurement volume (typically 0.3 cm³) and sophisticated analysis software enables highly sensitive measurements of gas transmission.

- The measurement principle used means that the requirements for generating a vacuum are relatively low. As the starting pressure level has no impact within a broad range (up to 10 hPa), all that is needed is a simple rotary vane pump.

- Its ability to directly measure the gas transmission of a wide range of different test gases significantly increases the number of potential uses for this device. For instance, the properties of the materials being tested can often be measured much faster and more precisely. The device does not require any modifications, let alone any intervention, to be used for different test gases.

- The device comes with a gas-saving mode in which the flow rate of the test gas can be reduced to approximately 1.2 l per hour – in other words, for example, that the contents of a small 10 l bottle can give 60 days of uninterrupted measurement.

- Several measurement modes enable values including the time lag to be calculated. This is needed in order to determine further physical properties such as the solubility or the diffusion coefficient of the sample.

- The temperature is controlled electrothermally by ultra-precise, energy-efficient Peltier elements during the sampling process, covering the full temperature range of 15 °C to 45 °C that is conventionally used for measurements. This gives the user numerous options for measuring other material properties, such as the activation energy.

- Potential uses for the GTT even include humidified test gases thanks to a digital sensor located right inside the top sample chamber that relays continuous measurements of the relative humidity and temperature of the test gas.

Technical Details

| Test method | Quantitative determination of the Gas Transmission Rate of film materials using differential pressure methods (manometric methods) according to ISO 15105-1 |

| Test gas | All non-corrosive, inert gases |

| Gas flow of the test gas | 50 cm³/min approx. | 20 cm³/min using test gas save mode |

| Measuring Range | 0.05 cm³/(m²×d×bar) to 20.000 cm³/(m²×d×bar) [up to 10E6 cm³/(m²×d×bar) with masking] |

| Resolution | 0.01 cm³/(m²×d×bar) |

| Pressure sensor permeat pressure | piezoresistive element, temperature stabilised |

| Range | 0 hPa to 1000 hPa (1,2 bar max.) |

| Tolerance | better 0.3 % FS |

| Resolution (display) | 0.01 hPa |

| Resolution (internal) | 0.01 Pa (24 bit) |

| Pressure sensor test gas | 0 hPa to 1200 hPa |

| Tolerance | better 1% FS |

| Resolution (display) | 0,1 hPa |

| Humidity sensor test gas | 10 % R.H. to 90 % R.H. |

| Tolerance | better 3 % |

| Temperature sensor test gas | 0 °C to 80 °C |

| Tolerance | better 3% |

| Sample temperature range | 15 °C to 45 °C |

| Tolerance | better 1 °C |

| Temperature constancy | better 0.2 °C |

| Control | in-build, 10” touch panel PC, high industrial standard |

| Dimensions | approximately 45 x 50 x 30 cm |

| Weight | approximately 23 kg |

| Storage temperature | 0 °C to 50 °C |

| Working temperature | 20 °C – 26 °C (to be constant during testing) |

| Relative humidity | max. 80 %, non-condensing |

| Electrical connection GTT | 100-115 VAC / 220-240 VAC, 50-60 Hz, power consumption approx. 150 W |

Optional accessories

Extensions

- Humidity Control

- User Access Control

- Sensor adjustment Software

- Integrated vacuum pump